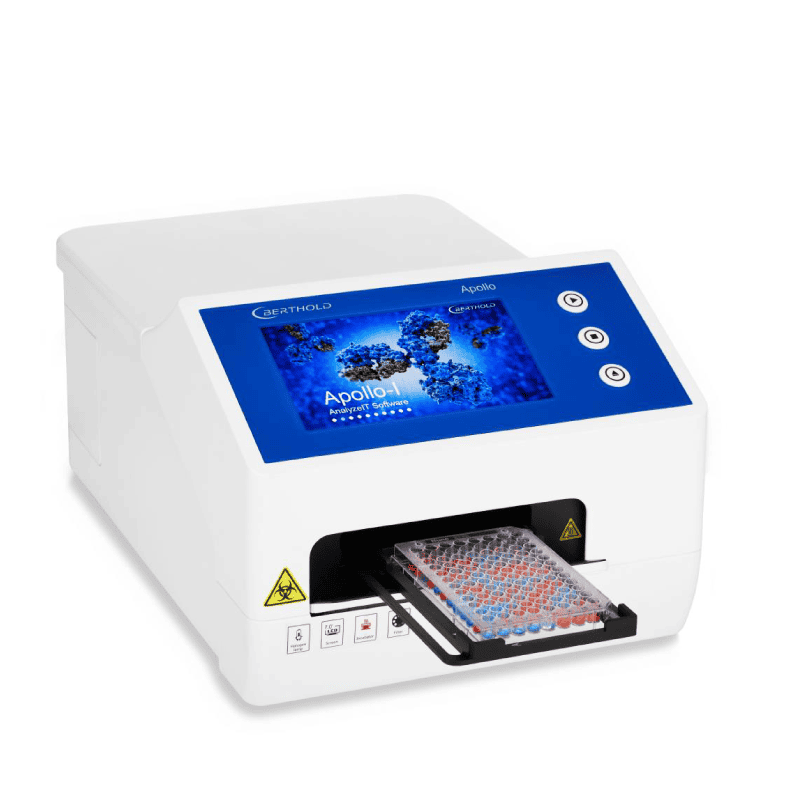

The Zoom HT microplate washer is a modular system that offers unmatched speed in washing microplates in 96- and 384-well formats. The compact systems enables automated high-throughput plate loading by means of a built-in stacker. Complemented with the optional 2-channel Dispense Module, the Zoom Washer becomes a highly efficient plate coating system.

Designed for high throughput applications, this multifunctional washer helps you increase productivity and efficiency.

Designed for speed

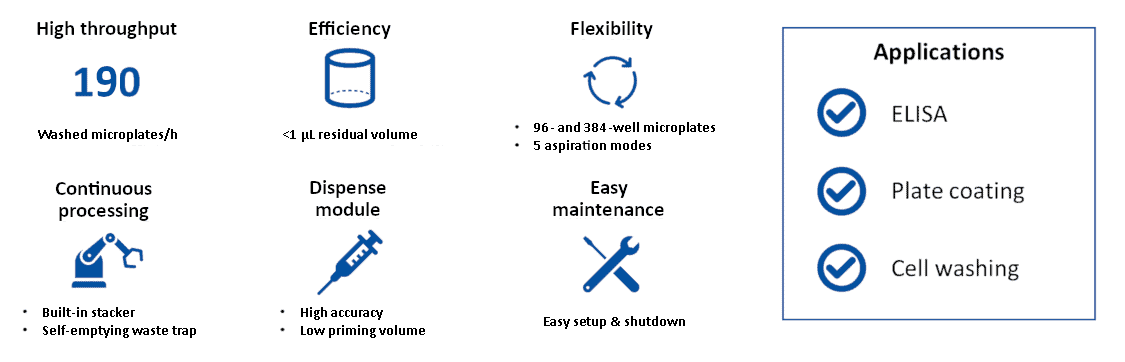

If your application requires to wash many microplates in a short time, the Zoom HT has you covered. The system combines several product features that enable high throughput while delivering excellent wash results:

- The Zoom HT takes only 14.5 seconds for a triple wash of a 96-well plate using point aspiration, 17 s including stacking.

- The self-emptying liquid discharge system, combined with a built-in stacker, ensures uninterrupted processing of large batches of plates.

- The single-rail plate transfer design enables highly efficient transfer of the plate from the in-stack to the wash position and from there to the out-stack position. Typical throughput is 190 washed plates per hour or up to 1,330 plates per day.

Designed for low residual volumes

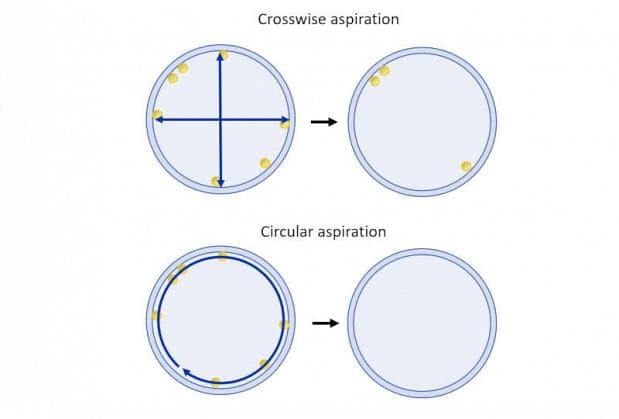

The Zoom HT is designed to achieve the desired residual volumes due to the flexible 3D-positioning of aspirate needles and the unique, reliable vacuum system used. In addition, the new circular aspiration function enables lower residual volumes than ever before: <1 μL/well.

Designed for reliability

The continuous addition of antifoam reagent to the liquid waste trap, and the ability to optimize dispense position and speed, make the Zoom HT ideal for handling problematic reagents.

Liquid level sensors alert the user if the reagent bottle is empty or the waste container full.

In addition, protocols can be protected from unwanted modification using the administrator mode.

High-throughput Dispensing

With the addition of the optional dispense module, the Zoom HT Washer becomes an efficient washer-dispenser combination system. Berthold uses a proprietary syringe-based liquid delivery system for reagent dispensing. The dispenser ensures timely and accurate one- or two-channel reagent dispensing with minimal dead volume (which helps saving precious reagents), perfect for microplate coating applications.

Plate Coating

The Zoom HT Microplate Washer & Dispenser satisfies all plate coating demands:

- High throughput thanks to its integrated stackers and single-rail design: it can coat or block up to 330 plates/hour, and wash (3x) up to 190 plates/hour.

- Clogging is prevented thanks to the large diameter of its dispense and aspirate needles and automated rinse and clean-out routines.

- Foaming is prevented thanks to the ability to optimize dispense position and speed, and the possibility to continuously add an anti-foaming reagent the liquid waste trap.

- Lowest residual volumes thanks to 3D-positioning of the aspiration needles and its powerful vacuum system with a constant and stable flow rate.

- Daily setup and shutdown normally involve only running the integrated rinse and cleaning routines; waste management is extremely simplified thanks to its self-emptying waste trap, with automated addition of sterilization reagent, if necessary.

Infographic Streamline ELISA kit manufacturing

Master challenges with high-throughput microplate washing and coating

Applications

ELISA

The Zoom HT dramatically reduces the number of wash cycles required. Residual volumes of <1 μL/well help you increase your assay reproducibility.

Plate coating

Equipped with the optional dispense module, the Zoom HT enables walk-away plate coating and manufacturing workflows, resulting in ready-to-use plates.

Cell-based assays

When performing cell-based assays, the Zoom HT effectively reduces background and allows for less variation, improving data quality and Z᾿-factors.

Technical Details (ZOOM HT WASHER)

Wash head: 96 channel wash head for fastest processing of 96 and 384 well microplates

Microplates: 96 well plates and strips, 384 well; Dimensions according to ANSI SLAS

Stacker: One-rail design connecting wash, dispense, and storage positions in short distance on one level

Dispense volume: 5-300 µL

Shaking: Up to 80 s, amplitude 1 mm, frequency 12 Hz

Aspirate Tip Descent Speeds: Slow / Medium / Fast

Soak Time: 0-99 s

Wash modes: Regular and Superwash

Number of Programs: 1-50

Wash Cycles per Program: 1-99

Wash Fluid Selection: 4 inlets

Protocol Protection: Administrator mode to prevent unauthorized changes

Wash head dispense accuracy: ±2% typical @200 µL

Wash head dispense precision: CV ≤2.5% @ 200 µL

Residual volume: <1 µL/well

Plate processing speed:

96-well plate, 300 µL (3 cycles, point aspiration): 14.5 s

96-well plate, 300 µL (3 cycles, point aspiration), including stack: 17 s

96-well plate, 300 µL (3 cycles, crosswise aspiration), including stack: 18.5 s

Dimensions (W x D x H): 589 x 420 x 645 mm

Weight: 26.3 kg

Liquid path materials: Stainless steel, Teflon®, PVC, Norprene, Silicone, Polysulfone

Operating voltage: 24 VDC ± 5%

Max. current consumption: 3.0 A

Protection class: III

Certifications: CE, UKCA

Temperature range:

storage: 0° to 40°C

operation: 15° to 35°C

transport: -20° to 50°C

Humidity:

10 – 80%, not condensing

maximum relative humidity of 80 % for temperatures up to 31 °C. Decreasing linearly to 50 % relative humidity at 40 °C.

Altitude: Max. 2000 m above sea level

Pollution degree: 2

Power supply Type: Desktop power supply

Input: 100-240 VAC ±10%, 50/60 Hz

Output: 24 VDC / 3.75 A

Protection Class: I

Energy efficiency: Level VI

Zoom HT LB 920 Plate Stacking Action

Zoom HT LB 920 Plate Stacking Action

For more information please email info@scienze.nz and one of our technical specialists will contact you directly to discuss your needs.

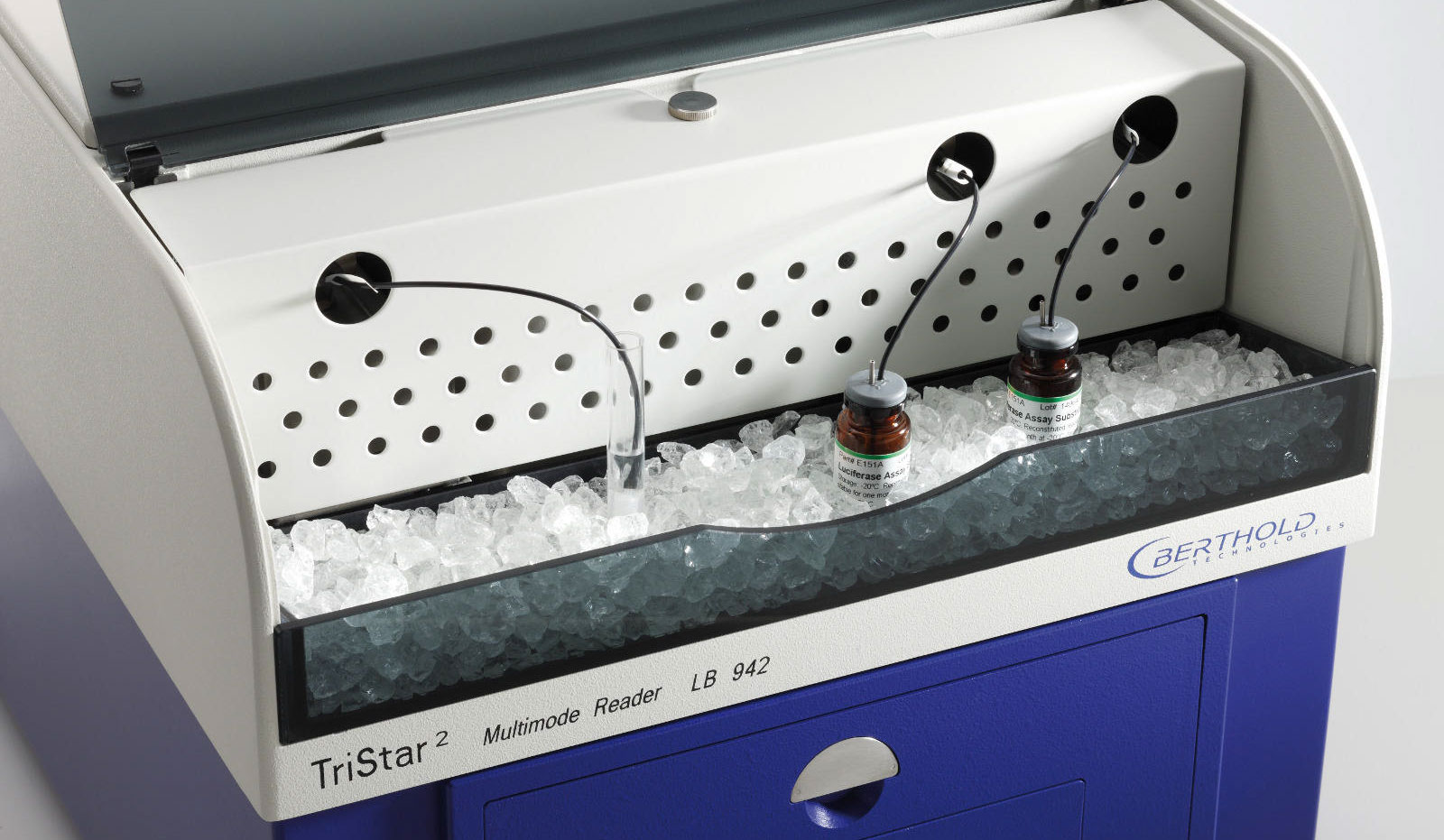

Berthold's comprehensive line of reliable Microplate Readers deliver the versatility, sensitivity, precision, dynamic range and throughput you need to solve your complex analytical challenges. Every lab is unique. That's why you deserve a Microplate Reader that fits your needs. Maybe your research requires maximum application flexibility, or high throughput. Perhaps you are looking for simplicity, delivering reliable results. Whatever you need, there is a Berthold Technologies Microplate Reader to fit your research needs.

Berthold Technologies Bioanalytics unit manufactures highly sensitive measuring systems for analytical and biomedical research, and devices for use in clinical diagnostics. Berthold is renowned for their luminometers with thousands of instruments installed all over the world. Other product groups are multimode readers, fluorometers, photometers, imaging systems, gel documentation, HPLC detectors and gamma counters.

Berthold Technologies develop new instruments for the latest measurement technologies in close cooperation with customers in universities, clinical institutes and the pharmaceutical industry.

Today, Berthold Technology looks back with pride on 60 years of a company history characterised by pioneering innovations, technological progress and strong growth. Berthold Technologies headquarters is located in Germany, Bad Wildbad, Northern Black Forest.

Need more information / Questions?

Need more information / Questions?

Please contact us by phone or email:

Freephone 0800 724 633

Or use the contact form below:

A to Z Product Listing

A to Z Product Listing

Copyright © 2025, Scienze. All rights reserved.